This post contains a follow up on the NEM white paper written by solar industry leader Josh Weiner, Solar Expert Witness . Mr. Weiner has been at the forefront of the solar energy industry for over 20 years and is an industry leader on solar-plus-storage engineering & design. Josh’s expertise spans both in-front of and behind-the-meter initiatives including residential, commercial, utility, grid-scale, and ev charging solar and storage applications.

UPDATED: The CPUC has unanimously passed this California NEM Storage decision on January 31, 2019. The information in our white paper reflects the final decision.

In December, SepiSolar published a white paper that reviews a proposed CPUC decision to include net energy metering (NEM) with DC-coupled energy storage for commercial solar systems. As of the writing of this blog post, the CPUC is set to vote to finalize the decision on January 31, 2019, and is expected to pass. However, it’s possible the vote will be postponed due to other priorities, such as PG&E’s bankruptcy filing. (Check the latest CPUC agenda here.)

While our white paper describes many of the financial benefits to the decision, several energy storage and inverter manufacturers had questions about the firmware solution that we designed for NEXTracker’s NX Flow system, a DC-coupled energy storage system.

Below is a list of some of these questions and the answers. As always, if you have more questions, please submit them in the comments section or send them to blogs@sepisolar.com.

Is DC-coupled storage with net metering approved in California only with NEXTracker’s NX Flow product?

As soon as the CPUC approves the policy change (hopefully by the end of January 2019), the NX Flow would be immediately eligible, since its firmware has already been verified by UL. However, other DC-coupled storage manufacturers may design similar firmware for their products. Eventually, UL will update their 1741 standard to include these protocols. In the meantime, utilities are allowing discretionary approvals of this policy, even though the CPUC hasn’t fully adopted it yet.

The white paper says that SepiSolar co-developed the firmware. Does that mean that energy storage or inverter OEMs need to license the code from SepiSolar or NEXTracker?

No. SepiSolar wrote the specifications, designed the testing protocol, and demonstrated the underwriting and verification process with our client, NEXTracker.

As with NEXTracker, OEMs will need to develop their own code and implement into their California NEM/Rule 21 compliant product after UL verification. Based on our experience, a manufacturer can typically develop the code within a day or so.

While SepiSolar does not write the firmware code, as an independent engineering firm, we’re able to help inverter and energy storage manufacturers with the functional and technical requirements to comply with this updated NEM energy storage policy for DC-coupled systems. Having gone through the UL process ourselves, we can advise on firmware design, testing pain points, pitfalls, and how to get through the UL approval process as expeditiously as possible.

Eventually, UL will update its 1741 standard to include the protocols that SepiSolar developed.

What do you mean by “firmware”? Don’t you mean “software”?

In order to adjust to this NEM storage proposal, utilities asked that the associated OEM software not be changed after interconnection, and that it be “hard-coded” into the hardware device’s “firmware” itself. They wanted to be certain that nobody could come back to the system later, after PTO (Permission to Operate) was issued, and re-program the battery to charge off the grid, thereby breaching the system’s interconnection agreement with the utility company.

While “firmware” involves software coding, it’s typically installed once at the manufacturer’s facility and implies that the software can’t be modified after installation or interconnection. On the other hand, “software” is inherently adjustable and can often be updated remotely by the system owner, OEM, or even third parties.

As a result, the “NEM software” (firmware) cited in the proposed CPUC decision must be hard-coded into the DC-coupled inverter device. It must then be recorded, tested, and verified by a Nationally Recognized Testing Laboratory (NRTL), such as UL or TUV. The inverter product must also have a specific version number and checksum that cannot be confused with other non-NEM-compliant hardware.

In the future, it’s possible that we’ll find ways to allow “un-editable” software to be located outside of the DC-coupled inverter device, perhaps in an EMS (Energy Management System) controller. However, the EMS would need to prove to the utilities that it, indeed, cannot be updated post-PTO. These alternatives are currently being discussed.

What happens if you update the firmware after interconnection?

As mentioned, the firmware protocol that SepiSolar developed ensures that the software is hard-coded by the OEM and verified that it was installed correctly by an NRTL. In our UL-verified protocol, if the firmware is changed after installation or interconnection, it will necessarily void the UL verification and put the entire installation in breach of its interconnection agreement (and Rule 21) with the utility. The utility will then be able to shut down the system and potentially fine the customer for any damages the utility may have sustained for the breach.

What are the firmware requirements?

The firmware requirements that any DC-coupled system would need to satisfy to receive NEM credits are fairly straight forward. It must be designed so that the battery can never charge from the grid. In addition, the firmware solution must be tested and verified by an NRTL, such as UL.

If you’d like to learn more about the specific tests themselves (there are 5 total), feel free to reach out to us at blogs@sepisolar.com, and we can share, specifically, what these tests entail. In summary, the tests involve:

1) The inverter’s ability to sense a potential “battery-charge-from-the-grid” event (which would violate this NEM policy) and mitigate it by controlling a DC bus voltage in order to turn the battery “off,”

2) The battery’s ability to be turned “on” or “off” by the inverter vis-à-vis this DC bus voltage control method described in (1) above,

3) The verification of software version number,

4) That no other software-controlled device (like an EMS) can override the inverter’s firmware, and

5) Sensitivity testing on all the above in the event that the PV supply varies widely (say, with variable cloud cover events).

Instead of inverters, can DC-DC converters adopt the firmware?

Yes. We see a clear use-case for getting a DC-DC converter approved under California NEM, but it would require a slightly different testing regime than the one we’ve developed for NEXTracker’s NX Flow product.

Is NEM with DC-coupled storage only available in California?

Yes, for now, due to this pending CPUC policy change, DC-coupled NEM with energy storage will only be available in California. However, other states typically follow California’s lead with policies like this. As of mid-January, 2019, we haven’t seen a system get approved outside of California.

***

We hope these responses answer your questions about the UL-verified firmware that is required for DC-coupled energy storage. If you have further questions, please add a comment or contact us at blogs@sepisolar.com.

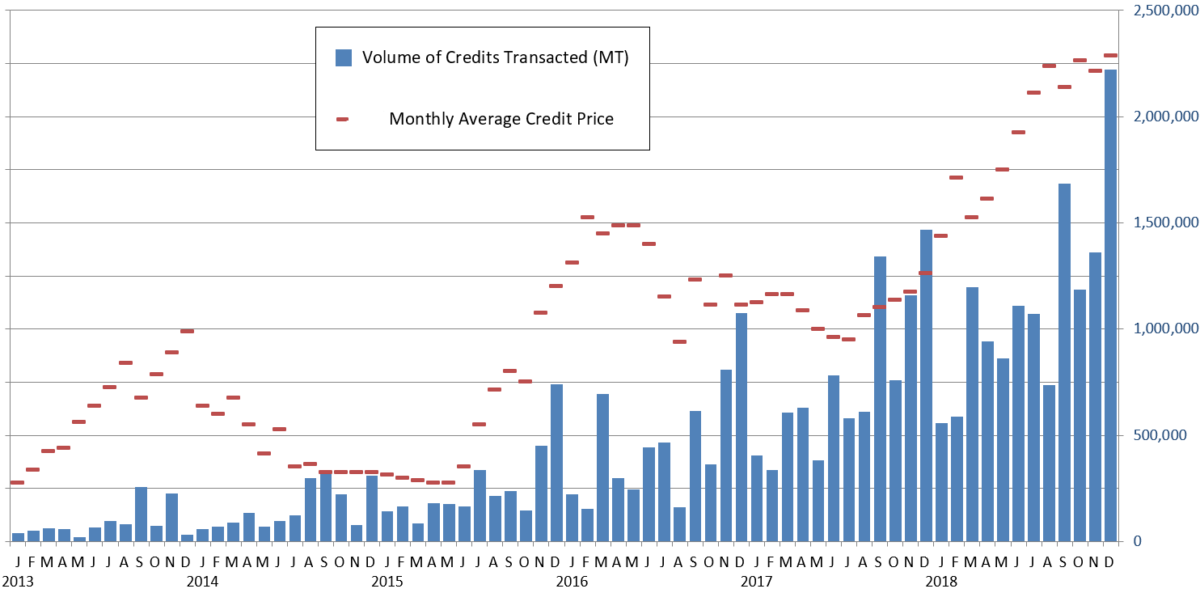

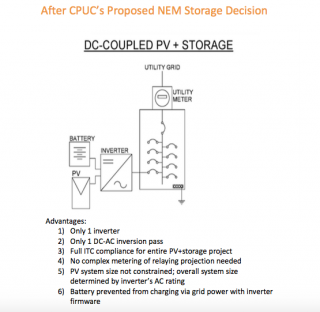

On Oct. 5, 2018, the California Public Utilities Commission (CPUC) issued a proposed decision to modify CPUC Decision 14-05-033, the NEM tariff policy for solar and energy storage. Once approved, the change will allow DC-coupled energy storage systems to become eligible for NEM without the need for thousands of dollars in extra hardware costs and burdensome verifications required by California utilities and the IRS for AC-coupled energy storage systems.

On Oct. 5, 2018, the California Public Utilities Commission (CPUC) issued a proposed decision to modify CPUC Decision 14-05-033, the NEM tariff policy for solar and energy storage. Once approved, the change will allow DC-coupled energy storage systems to become eligible for NEM without the need for thousands of dollars in extra hardware costs and burdensome verifications required by California utilities and the IRS for AC-coupled energy storage systems.