This post was written by Josh Weiner, Solar Expert Witness & Solar Engineering Expert. Mr. Weiner has been at the forefront of the solar industry for over 20 years and is an industry leader on solar-plus-storage engineering & design. Josh’s expertise spans both in-front of and behind-the-meter initiatives including residential, commercial, utility, grid-scale, and ev charging solar and storage applications.

It’s no secret that energy storage contractors have grown increasingly concerned about the safety risks associated with lithium batteries. While storage pairs nicely with solar technology and the industry seems poised for growth, a single incident could quickly change the narrative, as it already has in Arizona and South Korea.

SepiSolar CEO Josh Weiner invited Chief Electrical Engineer Richard Dobbins to the latest Quick Talk for ideas on designing safe and effective battery systems. See why Richard believes firefighters have an important role to play in permitting and inspections as installers continue to gain experience connecting storage to the grid.

Video Transcript

Josh Weiner: Hello and welcome. My name is Joshua Weiner of SepiSolar. I’m here with Richard Dobbins of SepiSolar. And we’re here today to talk a bit about lithium battery safety.

The way I actually see an engineering company like ours is—some people come to us asking for plan sets, some people ask us for technical advice and consul, or utility interconnection processing and PE stamps and whatnot.

I feel like all the services and deliverables that SepiSolar offers are all just a lot of different ways of calling ourselves risk managers. The name of the game for an engineering company like us is to really manage the risk on all the projects we touch.

And these risks, they can be safety related, they can be performance related, they could be upfront risks during the first few months of construction all the way downstream to the next twenty-five years of in-service operation because there’s risks all over the place on these projects.

And so I’m really happy to be here with you, Richard, because you are a licensed electrical professional engineer, right?

Richard Dobbins: Yeah, absolutely.

Josh: Could you just tell us a little bit about yourself? How long have you been at SepiSolar? What do you do for us?

Richard: I’ve been at the company about five years now. I’ve been a registered electrical professional engineer for about two of those.

Josh: Congratulations.

Richard: Thank you. I’ve been around since just around the inception of that marketable energy storage. My first few months on the job was diving right into battery storage projects and getting a feel for—back then, it was lead acid—type of systems. And so I’ve been kind of seeing the slow progression to where we are now with energy storage and utility scale. Something that really grew from where it was five years ago.

Josh: It’s an interesting point. When people talk about storage in the context of solar, it’s almost a given: we’re talking about lithium storage. It’s so ubiquitous now.

But it’s funny to remember that it’s actually only probably about five years old as a real commercial industry. I mean, for grid scale, for utility interactive applications behind or in front of the meter to do things like manage power, energy, on the grid.

It’s actually a very recent phenomenon. It’s been in laptops and cell phones for decades. But as a utility interconnected resource, it’s actually brand new. Well, great.

As an electrical professional engineer, safety—I assume—is a big part of your life. Is that fair to say?

Richard: I would say, yeah.

Josh: So, when you’re looking at lithium battery systems, what are some of the things you look at or look for or think about when you’re designing the systems for safety?

Richard: Safety is a huge concern with these projects.

I tend to look at safety from a two-pronged approach: passive and active. Passive safety, things like the enclosure that the batteries are contained in, the clearances that the batteries are from other equipment or from buildings and residences, things like that. There are certain distances that are required by code to keep those units away from potential risks, right?

And then you have active safety, things like the battery management system, things like fire suppression systems. In the case that a fire does break out in the unit, you can have a chemical extinguisher that puts it out or that stops the fire from propagating.

So really, between looking at those two sorts of approaches for safety, you can design an effective safe system that you can say with certainty that it will prevent catastrophic damage or loss of life.

Josh: I like your distinct delineation between active and passive. It almost sounds like the difference between quality assurance and quality control.

Quality assurance is something in the process or in the product you design. But then quality control is like a physical person, grabbing something, inspecting it, checking it, going down a checklist, and putting it into service.

And software is really good at that, right? Or BMSs and being able to—or people, human beings going in and checking something actively.

And then there’s the design aspect of it and engineering, what you try to do for it.

Well then how about common pitfalls that you see? Not only do we design engineer lithium systems, we get a lot of clients who ask us to review their lithium systems, either pre-construction or post-construction.

I’m just curious. What have you seen other people do with regard to lithium battery safety? And do you think it’s good? Do you think we got more work to do? Or how’s the industry doing from what you see out there?

Richard: I think as time goes on, the more exposure that people have to these kinds of projects, the more comfortable they’re going to be with the designs that they come up with or the first thoughts they have, right? The first pass of the design. Things like clearances and separation distances and even in the enclosure, like the passive elements that I mentioned before.

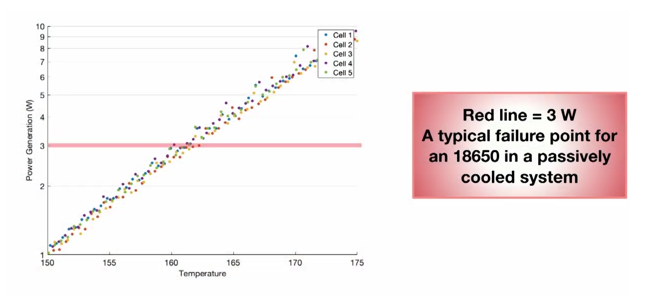

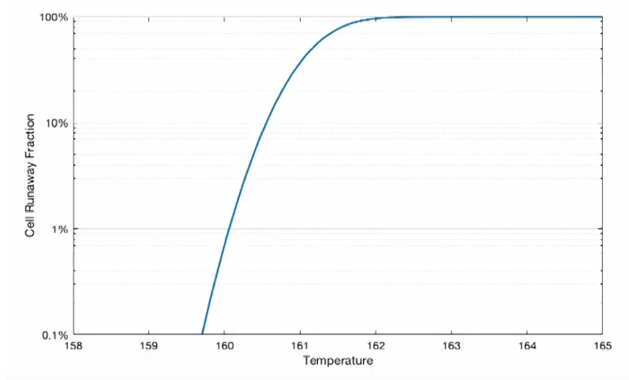

Those tend to get overlooked at the beginning, right? Most people who are used to PV systems are used to clearances for ventilation or for working clearances, you know, three feet and all that. With lithium batteries, it has to be a lot greater because of the risk of fire.

Josh: And that’s kind of what happened with APS’s battery fire, I think, too. Actually that was a case where there was a meltdown of a specific pack in a specific rack, and it melted into an aluminum pile (or molten metal pile) but then the saving grace, if you will, or the lesson learned, was because of the spacing in between the different racks.

Yes, there was a fire. We can talk about how it’s inherent to the technology; there may be nothing we can do about it. But, with some good spacing and ventilation requirements, we can at least prevent it from propagating, going from a little problem to a much bigger problem.

Richard: And that’s a big thing I have. Space is always an issue, right? With designers and with contractors. They want to fit as much as they can in the smallest space possible. They don’t want to waste space. So they want to densely populate the area, right? They want to fit as many batteries as they can. But you have to take into account that safety clearance.

Josh: That’s a serious kind of juxtaposition or conflict of interest. One of the promises and one of the promotions of lithium batteries is that they are so energy dense and don’t require a lot of footprint.

But that ends up being one of the risks, when you have that much energy too tightly packed, you end up with these problems like luckily with the APS battery fire was able to avoid in this particular case.

And then there are standards like NFPA 55, UL9540, with and without the A. Do you think these are adequate? Is the industry evolving to a point where all the codes are done and standards are done and everybody’s safe? Just follow the guidelines? Follow the rules?

Richard: I think that’s heading in the right direction. We obviously still have a lot to learn, as evidenced by the issues, the failures, that are breaking out, the ones we read about in the news, the ones we hear about through the grapevine.

There is a lot of work to be done with the safety regulations and just the industry catching up to those regulations. But we are definitely headed in the right direction with requiring those to be followed.

Josh: Do you think there’s a reason why folks underestimate the risks of lithium batteries? I mean, I almost feel like it’s a given. As I mentioned earlier, when we talk about battery storage, we just know we’re talking about lithium battery storage. Why do we just go straight to that? And are we underestimating the risks? And if so, how?

Richard: I think it just comes down to the age of the technology and the general awareness of the population. Like you mentioned at the beginning: It’s everywhere. But it’s only been maybe the last five years that people started plugging into their houses and using it to control their utility energy.

Josh: Do you think they’re so comfortable with it in their cell phones and laptops and now cars that—it’s just: “Yeah. OK, it’s already in everything. Just throw it on the side of the house. Back up my loads when the grid goes down.” It doesn’t even factor into the equation.

Richard: I think so. And to your point about energy density: the amount of lithium in your phone or in your laptop is really small compared to the amount of lithium that you’re going to be installing to back up your house or to create demand charge mitigation. It’s a huge difference. And with that much density comes a much higher risk of fire, of a failure.

Josh: What would you recommend? What should people be thinking about or doing when they design for these, when they build lithium systems, given that the codes need more time to evolve, given that we’re learning and we’re on this trajectory?

And when we talk about storage, we just immediately talk about lithium. What are the things you think we should be doing as an industry or us, SepiSolar, as the licensed engineers that are sealing and complying with codes and following through on these safety precautions?

What should people like us and others be doing?

Richard: I think it’s all about awareness.

Numerous projects I’ve worked in the past, it was very much a learning experience for mostly everyone involved, especially on the part of fire departments. They’re very concerned with lithium batteries being installed.

And it’s their job to mitigate, to ensure fire safety. So they get very involved in the permitting process when it comes to lithium batteries. And so I think getting fire departments involved and educated on the technology and the safeties that are involved is really going to help go a long way with getting everybody as a whole, and really enforcing it as part of the permitting process and the safety inspection process.

Josh: I like the suggestion of collaborating with the officials who know a thing or two about fire.

For example, some of the things that the solar industry is not good at—historically—have been things like software.

The construction industry, it’s a very hardware-driven industry. We’re putting big, heavy machinery and we’re doing very high-risk operations and activities on buildings and structures. So it’s very risky work.

And if we’re not aware of the issues, it’s like the twelve-step program, you know? The first step toward recovery is admitting you have a problem.

First, you’ve got to be aware of it, and then you can address it. And by collaborating with the experts who know a thing or two about all this, we’ll get smarter as a whole.

That seems to make a lot of sense. And again, the essence of risk management: maybe we don’t have all the answers, but by being aware of what the risks are, we can surface sometimes highly nuanced issues and work with our customers to decide what the best plan is for that.

Richard: Yeah, absolutely.

Josh: Makes sense. Well, thanks so much for joining us.

We’re going to have many more conversations like these about not just battery safety, but also we’re going to talk about battery performance and the state and evolution of the market with various technologies and different benefits and costs associated with each of those.

Really excited to talk more about that. Please join us at SepiSolar.com. You can read much more on our blog about information we’ve published along these lines, as well as following us on Twitter and LinkedIn.

Looking forward to talking more about this with you soon.